CATEGORY

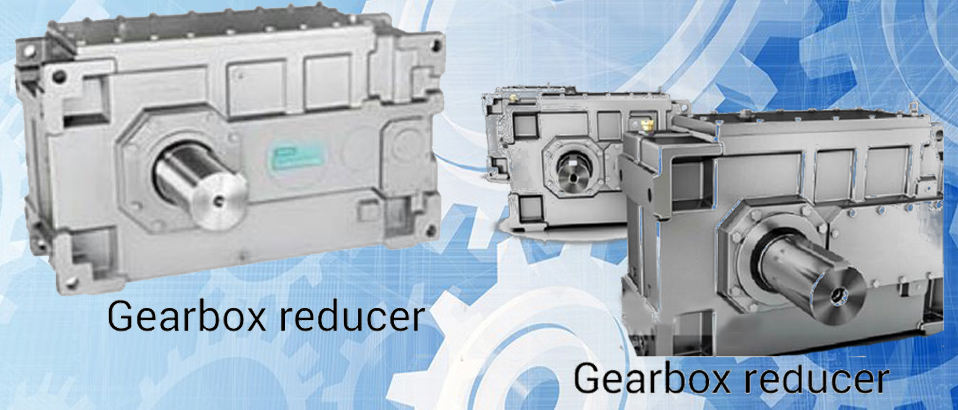

GEAR UNIT/GEARBOX FLENDER SIEMENS

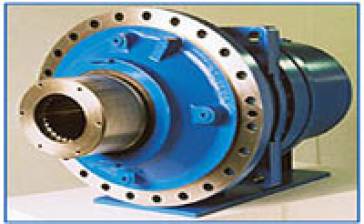

Planetary Gear UnitsThis series includes more than 27 sizes. The gear units comprise two or three planetary gear stages which can be combined with different primary gear stages. Primary gear stages can be either helical or bevel gear stages or a combination of bevel and helical gear stages.

DescriptionThis series includes more than 27 sizes. The gear units comprise two or three planetary gear stages which can be combined with different primary gear stages. Primary gear stages can be either helical or bevel gear stages or a combination of bevel and helical gear stages.

Advantages:

• Modular design system = Multi-purpose use of the housings and internal components

• Optimum load distribution between the planet gears, among other things owing to high manufacturing accuracy and Finite-Element calculation method (FEM calculation) of the planet carrier

• Three or four planet gears

Examples of applications:

• Roller press drives

• Slewing gear drives

• Bucket wheel drives

• Apron conveyor drives

• Separator drives

• Agitator drives

• Travelling gear drives

• Steel band rolling mill drives

• Rotary kiln drives

Advantages:

• Modular design system = Multi-purpose use of the housings and internal components

• Optimum load distribution between the planet gears, among other things owing to high manufacturing accuracy and Finite-Element calculation method (FEM calculation) of the planet carrier

• Three or four planet gears

Examples of applications:

• Roller press drives

• Slewing gear drives

• Bucket wheel drives

• Apron conveyor drives

• Separator drives

• Agitator drives

• Travelling gear drives

• Steel band rolling mill drives

• Rotary kiln drives